Epoxy Flux Paste (without filler)

Application

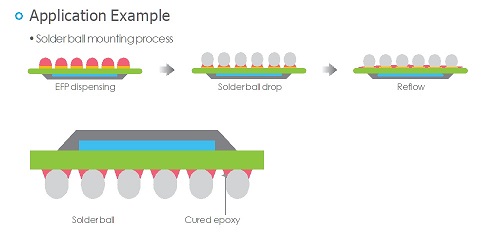

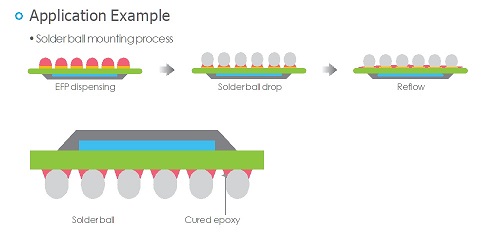

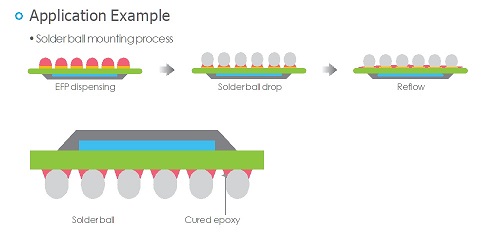

- Reinforcement of bump edge by fillet formation after mounting of solder balls

- Stack chip package

- Package on package (Pop)

- Flip-chip semiconductor underfill

- BGA package underfill

Characteristics

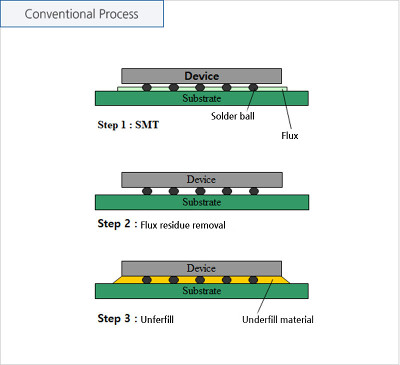

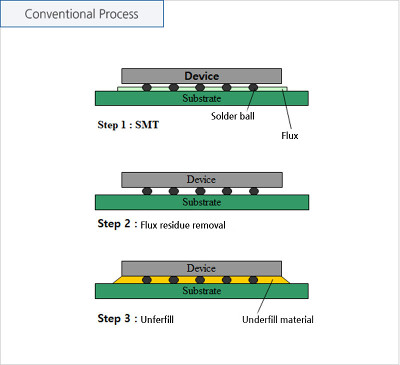

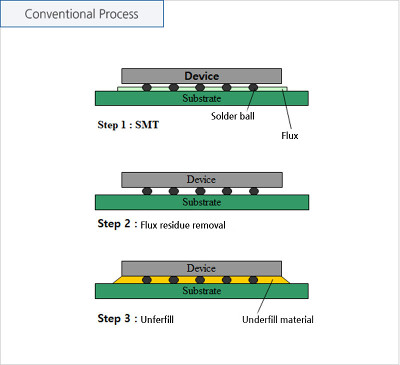

- Reduces the existing flip-chip process and underfill process into a single process

- Increases productivity by reducing the number of process

- Fluxing effect the metal oxide film on package lead, solder ball, and Cu pad

- Solvent-free, cleaning-free,corrosion-free

- Customized formulation (viscosity, curing temp, Tg, etc)

Epoxy Flux Paste (with filler)

Characteristics

- No-flow underfill material

- SiO2, filler content : 10-70 wt%

- SiO2, filler size: 0.2 - 4 um

- Customized formulation (viscosity, curing temp, curing time, Tg, etc)

Application Field

- Mounting of driver IC chips on film flip chip package

- Mounting of application processors on flip chip package

- Fine pitch I/O flip chip package